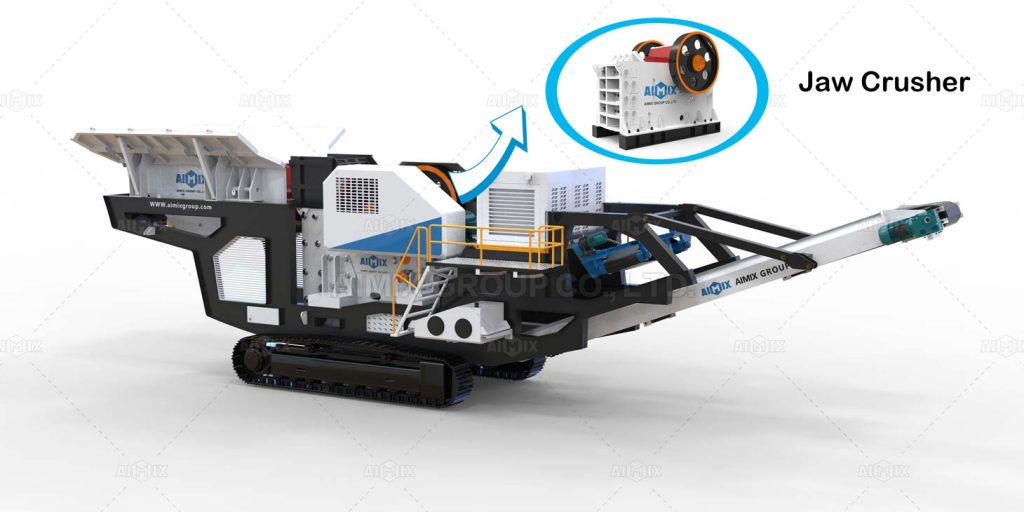

In the realm of crushing equipment, jaw crushers on tracks represent a specialized subset of machinery designed for optimal mobility and efficiency in diverse construction and mining applications. These track-mounted crushers, also known as track-mounted jaw crushers, offer distinct advantages over their stationary counterparts. Let’s delve into the definition and functionality of jaw crushers on tracks to understand their unique characteristics better.

Definition of Jaw Crushers on Tracks

Jaw crushers on tracks are crushing machines mounted on mobile platforms, equipped with tracks or crawler systems for enhanced mobility. Unlike stationary jaw crushers that remain fixed in one location, jaw crusher on tracks can navigate rugged terrains and access remote sites with ease. This mobility facilitates on-site crushing operations in various construction and mining environments, allowing for efficient material processing directly at the point of extraction or construction.

Functionality of Jaw Crushers on Tracks

The functionality of jaw crushers on tracks revolves around their ability to move seamlessly across different job sites and adapt to changing operational requirements. These crushers feature robust jaw plates that exert compressive force on the feed material, breaking it down into smaller fragments suitable for further processing. With the added advantage of mobility, operators can transport mobile crushing plant to different locations swiftly, reducing downtime and maximizing productivity.

Comparing Jaw Crushers on Tracks with Stationary Jaw Crushers

While both track-mounted and stationary jaw crushers serve the primary purpose of crushing rock and ore materials, significant differences exist between the two types of machinery. Let’s explore these disparities to gain insights into their respective strengths and applications.

Design Differences

One of the most noticeable distinctions between jaw crushers on tracks and stationary models lies in their design and construction. Track-mounted jaw crushers feature robust chassis equipped with tracks or crawler systems, allowing for seamless mobility across various terrains. In contrast, stationary jaw crushers are typically mounted on fixed foundations or structures, limiting their mobility to a specific location. This design variance enables track-mounted crushers to access remote or challenging sites inaccessible to stationary crushers, making them ideal for on-the-go crushing operations in dynamic environments.

Functionality and Performance Variances

Beyond design disparities, differences in functionality and performance distinguish track-mounted jaw crushers from their stationary counterparts. The mobility afforded by track-mounted crushers enhances their operational flexibility, enabling operators to deploy them closer to the point of material extraction or construction.

This proximity minimizes transportation costs and reduces the need for additional machinery, streamlining the crushing process and improving overall efficiency. Moreover, track-mounted jaw crushers boast superior maneuverability, allowing them to navigate confined spaces and rugged terrains with ease, where stationary crushers may struggle to access. These performance advantages make track-mounted jaw crushers the preferred choice for mobile crushing applications across diverse industries. You can have a better understanding of its function through AIMIX crusher plant video below.

This article provides a comprehensive overview of jaw crushers on tracks, elucidating their unique features, operational dynamics, and comparative advantages over stationary jaw crushers. By understanding the distinctions between these two types of crushing equipment, industry professionals can make informed decisions when selecting the most suitable machinery for their specific needs.